How to Use FFC Test Equipment: A Step-by-Step Guide

FFC Fixture Assembly by Flexible Test

Flat Flex Connectors (FFCs) are an integral part of many modern electronics, offering flexibility and space-saving advantages. Ensuring their performance through reliable testing is crucial to the success of your products.

At FlexibleTest, our specialized fixtures make this process easy and efficient. Beyond testing, our fixtures also support device programming, providing a versatile solution for electronics manufacturers. In this article, we’ll explore both of these use cases, demonstrating how FlexibleTest fixtures can enhance your production workflow.

Understanding Flat Flex Connectors

Flat Flex Connectors consist of flexible plastic with embedded conductive traces. They are used to connect various components in a wide range of electronic devices, from consumer gadgets to industrial machinery. Due to their delicate nature and critical functionality, testing and validating these connectors is essential before integration into any product.

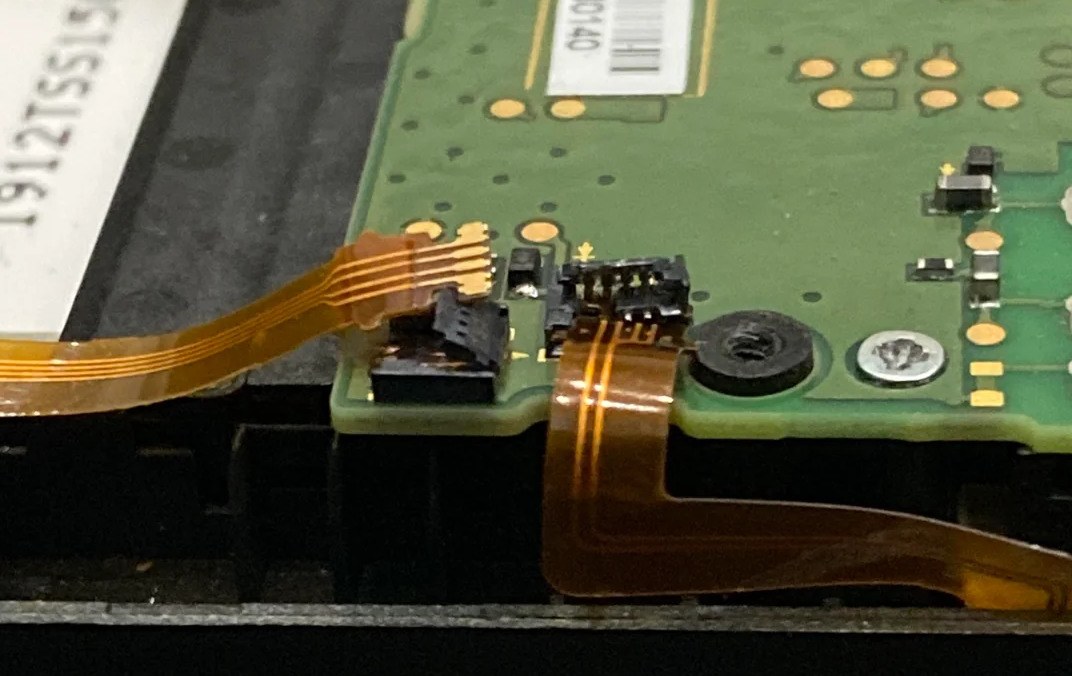

Flat Flex Connectors need to be tested to ensure that they are free from defects like open circuits, misalignments, or weak connections, all of which can lead to product failures. Testing is particularly vital in industries with strict reliability requirements, such as automotive, aerospace, and medical devices.

However, these connectors are fragile and are not rated for high cycle counts.

A pair of broken FFC connectors

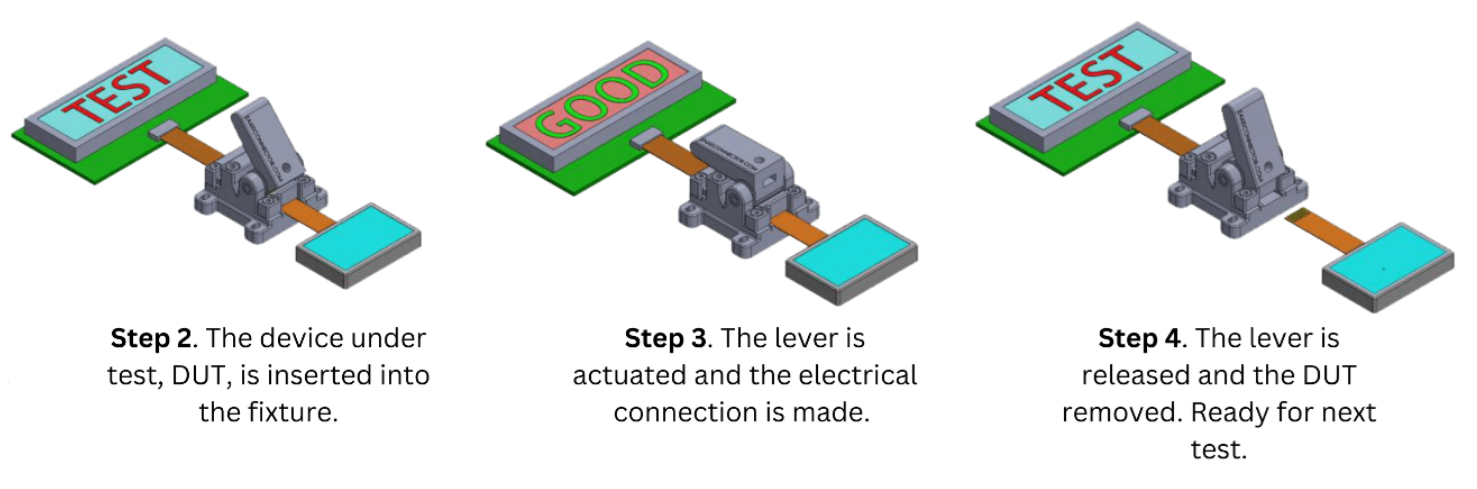

Step-by-Step Process for FFC Testing with Flexible Test Fixtures

a. Preparation

- Set Up the Test Fixture: Connect the test fixture’s terminating cable into your test equipment. This will serve as a semi-permanent connection, elevating the risk of wear to your test equipment connector.

b. Performing the Test

- Run Continuity Tests: These tests verify that all conductive pathways within the FFC are properly connected.

- High-Pot Testing: Apply high voltage to check the strength of the insulation between the conductors, ensuring that there are no potential short circuits.

- Measure Contact Resistance: Use contact resistance testing to identify areas where electrical resistance is too high, indicating a problem that could lead to malfunction.

c. Reviewing the Results

- Check for Pass/Fail Indicators: Modern test fixtures will give a clear pass or fail result for each connection.

- Investigate Failures: If any failures are detected, analyze the results to determine the root cause and make the necessary corrections before moving forward.

5. Device Programming with FlexibleTest Fixtures

In addition to testing, FlexibleTest fixtures also support device programming, providing a versatile solution for manufacturers who need to program microcontrollers, ICs, or other electronic components during the production process. This use case is distinct from testing but equally important for ensuring your devices function as intended.

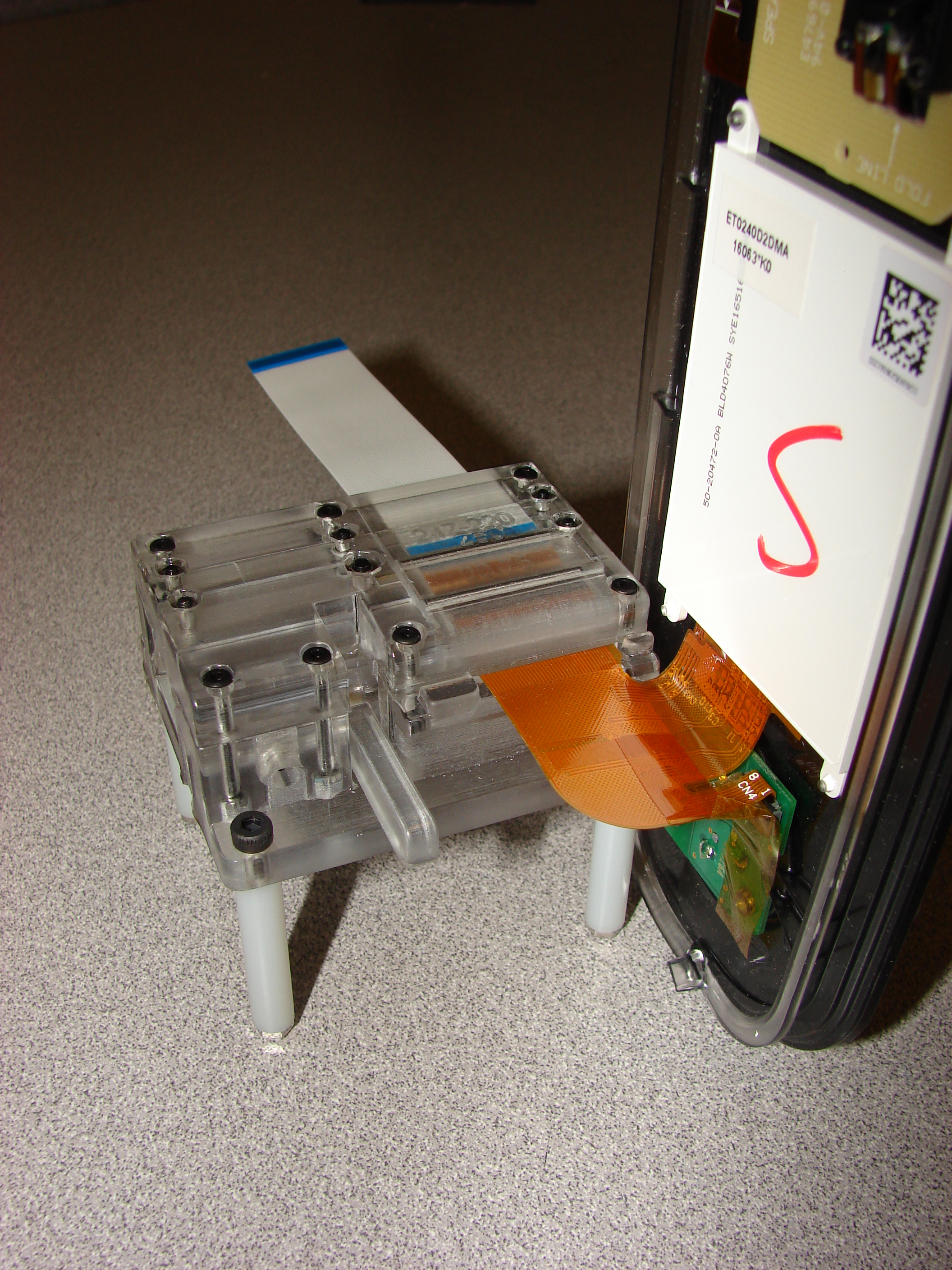

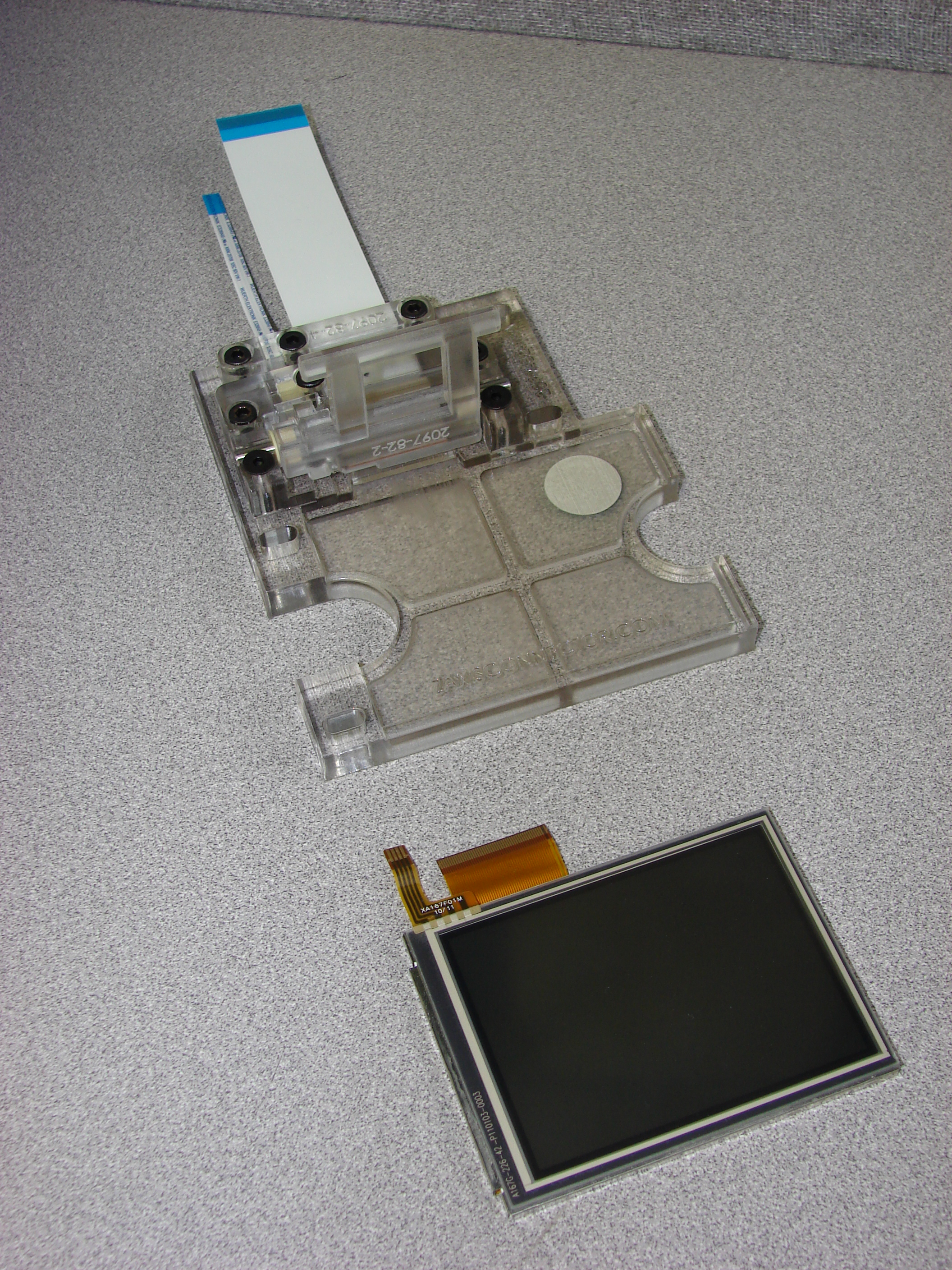

Fixture for Device Programming

a. Why Use Test Fixtures for Programming?

- Efficient Workflow: Our fixtures allow you to program devices as they are being tested or in a separate operation, reducing handling time and improving production efficiency.

- Accurate Contact: The same precise alignment that ensures proper testing also ensures reliable contact for device programming, minimizing the risk of faulty programming due to poor connections.

b. Programming Devices via FlexibleTest Fixtures

- Connecting to the FFC: By using the same test fixture, you can connect the FFC to program the embedded devices or components without needing additional hardware.

- Streamlining the Process: With the ability to program multiple devices simultaneously, you can significantly reduce programming time, especially in high-volume production environments.

- Ensuring Consistency: FlexibleTest fixtures offer consistent and repeatable programming, ensuring each unit is programmed identically.

c. Verifying the Programming

- Post-Programming Validation: After programming, the fixture can be used to validate the programming process, ensuring that each device is correctly programmed before it moves to the next stage of production.

6. Separating the Use Cases: Testing vs. Programming

While both testing and programming are key operations in the production process, they are distinct and serve different purposes:

- Testing: Focuses on ensuring the electrical and physical integrity of the FFC, identifying any potential issues before the final product is assembled.

- Programming: Involves loading firmware or software onto components, such as microcontrollers or ICs, during production. This can be done either in conjunction with testing or as a separate step using the same fixture.

Each of these processes is critical, and by using FlexibleTest fixtures, you can streamline both workflows, ensuring efficiency and reliability in your production line.

7. Common Mistakes to Avoid

- Skipping Inspections: Always conduct visual and mechanical inspections before testing or programming to avoid false results.

- Incorrect Fixture Alignment: Proper alignment in the fixture is essential for both accurate testing and reliable programming.

- Neglecting Test Data: Carefully review all test and programming data to ensure there are no issues before the product moves forward in the production process.

8. Conclusion

FlexibleTest fixtures are designed to simplify both flat flex connector testing and device programming, providing a robust solution for electronics manufacturers. Whether you need to ensure your connectors are defect-free or efficiently program multiple devices, our fixtures offer the accuracy, reliability, and speed necessary to keep your production process running smoothly.

By leveraging these fixtures for both testing and programming, you can streamline your operations, reduce errors, and deliver high-quality products with confidence.

Get in touch with FlexibleTest today to learn more about how our fixtures can meet your project needs.