Micro-Fixtures For Hard to Reach Areas

Micro-Fixture by Flexible Test

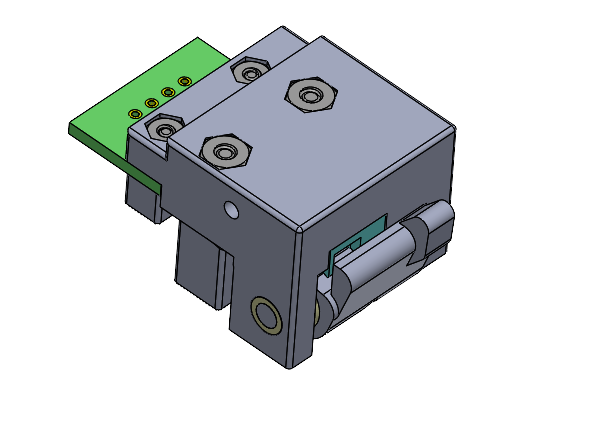

As electronics shrink in size, engineers and manufacturers face increasing challenges when it comes to testing and programming components in confined spaces. That’s where Flexible Test’s micro-fixtures come in—designed for users who need a small footprint without compromising on precision or functionality.

Why Micro-Fixtures?

When working with dense PCB assemblies, complex devices, or miniature components, traditional test fixtures can be too bulky to handle the task efficiently. Micro-fixtures are the ideal solution for situations that require highly precise testing in tight or hard-to-reach areas. Their compact design ensures that even the most intricate parts of a device can be easily accessed and tested.

Key Features of Flexible Test Micro-Fixtures:

- Compact Size: The micro-fixture, as seen in the image, is designed to be as small as possible while still delivering accurate results. This makes it perfect for environments where space is limited.

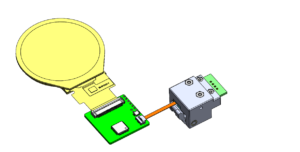

- Multi-Purpose Use: Our micro-fixtures are versatile, allowing you to test for various parameters such as continuity, signal integrity, and contact resistance, all within the same setup.

- Enhanced Access: By offering access to hard-to-reach areas, these fixtures make testing in confined spaces quick and efficient.

- Precision Performance: Even though our fixtures are small, they provide reliable, repeatable results, ensuring that every test is accurate.

- Durable and Long-Lasting: Designed to handle industrial applications, our fixtures are built to withstand repeated use without wear or performance degradation.

Typical Applications:

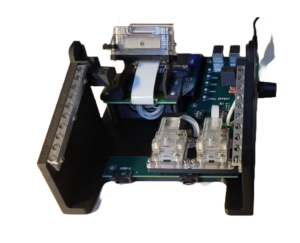

- Testing in Compact Assemblies: Micro-fixtures allow for testing components located in tight spaces within consumer electronics or industrial equipment.

- Prototype Debugging: Use micro-fixtures to validate and troubleshoot prototypes, where space and access are often constrained.

- High-Density PCB Testing: Ideal for testing high-density circuit boards where traditional fixtures would struggle to access key areas.

- Device Programming: Simultaneously test and program devices in small production runs or on compact test benches, reducing the need for separate equipment.

Benefits of Using Micro-Fixtures in Hard-to-Reach Areas:

- Space Efficiency: The small footprint of these fixtures means you can maximize your workspace while still performing comprehensive tests.

- Reduced Setup Time: Quick and easy to integrate, these micro-fixtures save time during the setup process, making them perfect for both development and production environments.

- Consistent Results: With precision alignment and robust design, our fixtures ensure that each test is conducted under the same conditions, leading to consistent and reliable results.

Conclusion

Flexible Test’s micro-fixtures are designed for engineers and manufacturers who need precision testing capabilities in hard-to-reach areas. Whether you’re performing high-density PCB tests or working with intricate devices, these micro-fixtures ensure accuracy without taking up valuable space.

Contact Flexible Test today to learn more about how our micro-fixtures can meet your specific testing needs.