A Case Study of Flexible Test’s Game-Changing Fixtures for Aerospace Testing

In the high-stakes world of the aerospace industry, precision and reliability are paramount. Every component, from engines to avionics, must undergo rigorous testing to ensure they meet the most stringent safety and quality standards. When a leading aerospace company found themselves facing recurring challenges with standard ZIF connectors, it threatened to ground their ambitious production goals. In search of a solution, they turned to Flexible Test and discovered a game-changing partner.

The Challenge: Standard ZIF Connectors Falling Short

The aerospace company, a renowned player in the industry, had dedicated substantial time and resources to crafting a state-of-the-art testing setup. The objective was clear: to ensure every component, big or small, met the rigorous safety and quality standards demanded by the aviation sector. However, this ambitious vision was soon hampered by a critical bottleneck – the Achilles’ heel of standard ZIF connectors.

Constant Breakdowns and Failures: A Nightmare Unfolds

ZIF connectors, while widely used, were known for their delicate and finicky design. The aerospace company found themselves in a constant battle with these connectors as they repeatedly broke and failed on their sophisticated test equipment. The repercussions of these breakdowns were felt across the board, and the challenges were undeniable.

1. Downtime: A Costly Interruption

- Each time a ZIF connector faltered, it spelled significant downtime for the aviation company. Highly skilled technicians were abruptly pulled from their critical tasks to diagnose and replace the faulty connectors. The interruptions were not only a source of frustration but also a financial drain, as every minute of downtime translated into lost productivity and potential revenue.

2. Soaring Maintenance Costs: A Budgetary Nightmare

- The frequent replacements and repairs of ZIF connectors began to take a substantial toll on the aviation company’s maintenance budget. The escalating costs were unsustainable and threatened to erode the financial stability of the testing operation. It was evident that a change was needed, not only to restore reliability but also to bring maintenance expenses under control.

3. Production Delays: A Supply Chain Domino Effect

- In the aerospace industry, time is a precious commodity. The company’s production requirements allowed no room for disruptions, and the consequences of delays caused by malfunctioning connectors could have a cascading effect, impacting the entire supply chain. Production schedules were at stake, and the aerospace company couldn’t afford the ripple effect of these interruptions.

In the face of these challenges, the aerospace company recognized the urgency of finding a solution that could not only restore reliability but also enhance efficiency in their testing process. This realization marked the beginning of their journey with Flexible Test, a partner that would prove instrumental in transforming their testing landscape.

The Search for a Solution: Flexible Test Enters the Picture

Frustrated with the continuous setbacks, the aerospace company decided to explore alternative solutions. They reached out to Flexible Test, a company known for its innovative approach to test fixtures.

Flexible Test’s team quickly got to work, understanding the unique challenges faced by the aerospace company. The goal was clear: to design and deliver fixtures that could not only meet but exceed the aerospace company’s expectations.

The Solution: A Partnership that Soared

Flexible Test’s commitment to innovation and engineering excellence shone brightly during this project. Here’s how their test fixtures turned the tide:

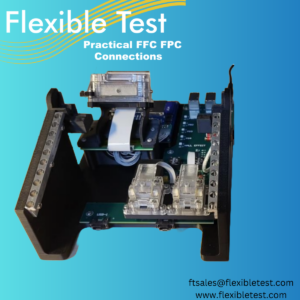

- Robust Engineering for Reliability: The key to Flexible Test’s success was their focus on durability. The engineered contacts in their fixtures were designed to endure thousands of cycles, eliminating the recurring issue of broken latches. This reliability meant that the aviation company’s testing process became far more predictable and dependable.

- Seamless Integration: Flexible Test’s fixtures offered a hassle-free drop-in solution, effectively bridging the gap between the aviation company’s Device Under Test (DUT) and test equipment. The straightforward setup eliminated the need for complex configurations or adjustments, ensuring that the integration process enhanced overall testing efficiency.

- Expert Support: The aerospace company didn’t just receive a product; they gained a partner. Flexible Test provided expert support, analyzing their needs and working closely with their team to craft efficient FFC test fixtures. This personalized approach not only improved the testing process but also saved the company valuable time and resources.

The results were nothing short of transformative. The aerospace company not only overcame the challenges that were plaguing them but also improved their overall testing process. Here’s how this partnership unfolded:

- Reduced Downtime and Maintenance Costs:

- The most immediate impact was the significant reduction in downtime. With fixtures that didn’t constantly break or malfunction, technicians were free to focus on their tasks. Maintenance costs plummeted as the need for frequent replacements and repairs became a distant memory.

- Enhanced Efficiency:

- The aerospace company’s testing process became remarkably efficient. With fixtures that seamlessly integrated into their setup, the testing workflow was streamlined, allowing them to meet their deadlines with confidence.

- Strong Partnership:

- The collaboration with Flexible Test didn’t end with the delivery of fixtures. It marked the beginning of a strong and enduring partnership. The aerospace company found a reliable and innovative ally to support their testing needs.

The aerospace company’s journey from frustration to success was a testament to the power of innovation and partnership. Flexible Test’s fixtures not only resolved their immediate challenges but also elevated their entire testing process, resulting in greater efficiency and cost savings.

A Testimonial of Success

We had the opportunity to speak with the aerospace company’s project manager, who shared his thoughts on this transformative partnership. He stated, “Working with Flexible Test was a game-changer for us. We were at a point where the constant failures of ZIF connectors were becoming a significant roadblock. Flexible Test not only provided us with reliable fixtures but also tailored their solutions to our specific needs. This level of customization and support has been invaluable to us. We’ve not only eliminated connector hassles but also improved our overall testing process.”

This case study demonstrates how Flexible Test’s commitment to innovation, durability, and personalized support can lead to remarkable results. In the demanding world of aviation, every advantage matters, and Flexible Test has proven to be a valuable ally.

Conclusion: Elevating Aviation Testing with Flexible Test

The aerospace company’s journey is a prime example of how a partnership with Flexible Test can transform the testing landscape. By addressing the challenges of standard ZIF connectors, Flexible Test’s fixtures not only eliminated frustrations but also paved the way for greater efficiency and cost savings.

In an industry where precision and reliability are paramount, Flexible Test’s commitment to robust engineering, seamless integration, and expert support has proven to be a winning formula. As aerospace companies continue to push the boundaries of technology, they can rest assured that Flexible Test stands ready to provide the innovative solutions they need to succeed.

Are you facing similar challenges in your testing process? It might be time to consider how Flexible Test’s fixtures can revolutionize your approach. Contact us today to explore solutions tailored to your unique needs and join the ranks of satisfied customers who have experienced the transformation firsthand.