Eliminate the risk of fragile ZIF connectors with Flexible Test

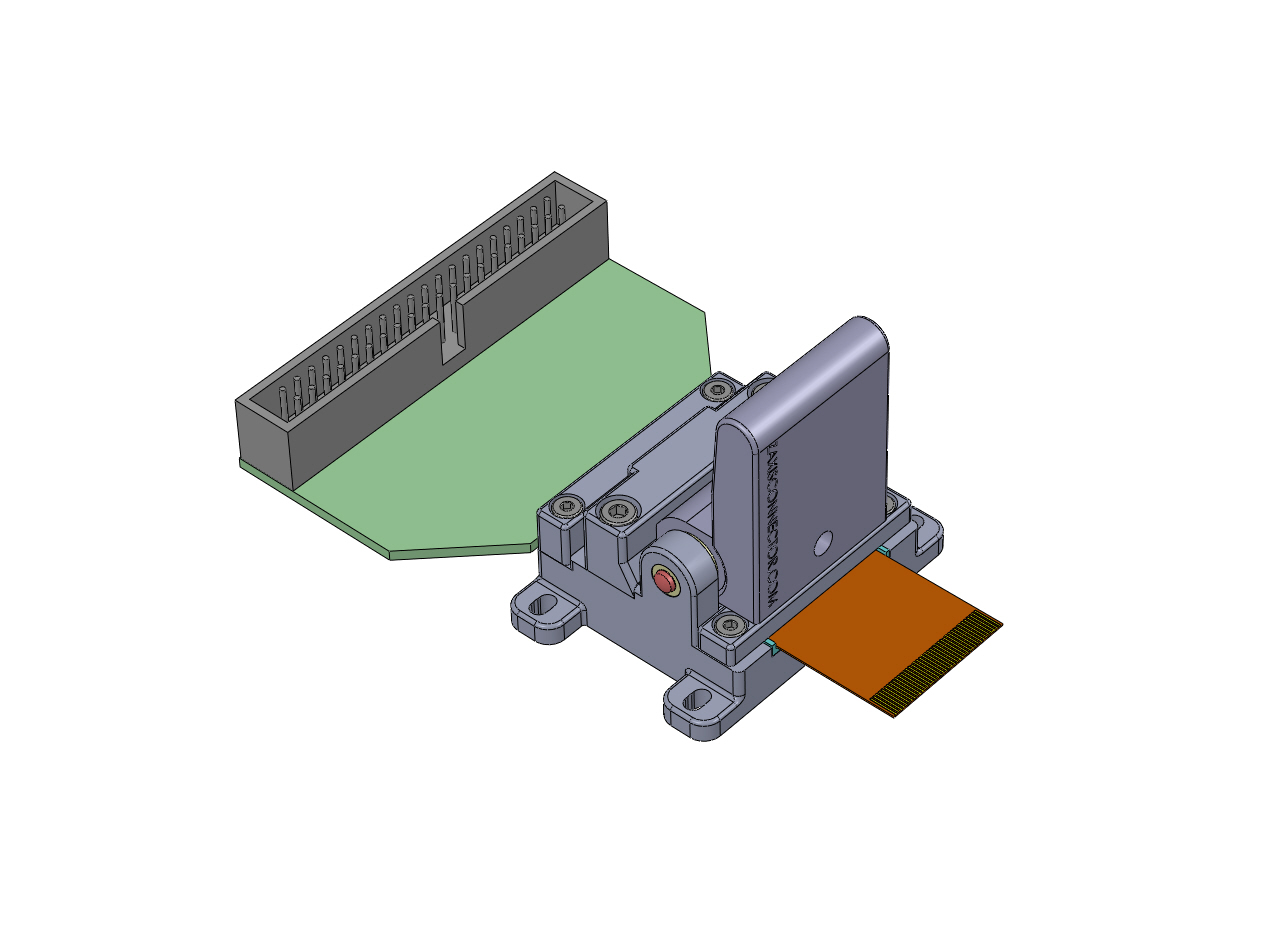

A PCB-Terminated Fixture from Flexible Test

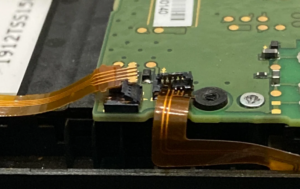

A significant technical bottleneck in today’s electronic technology is the fragility of standard ZIF connectors used to interconnect devices utilizing flat flex cables (FFCs).

These ZIF connectors, along with other similar connectors such as spring-loaded pins, pose several challenges that can hinder the reliability and efficiency of electronic testing and device assembly.

These ZIF connectors, and similar types, are not rated for high mate and de-mate cycling, making them a suboptimal choice for test equipment. They pose additional problems, such as misalignment and potential damage to the device from sharp pins.

Problems with Standard ZIF Connectors and Spring-Loaded Pins

- Low Cycle Life

- ZIF Connectors: These connectors are not designed for repeated use. The low mate and de-mate cycle count means they wear out quickly, leading to unreliable connections over time.

- Spring-Loaded Pins: While these pins can handle more cycles than ZIF connectors, they still wear out relatively quickly, especially under high-frequency use.

- Signal Degradation

- ZIF Connectors: Over time, ZIF connectors can suffer from signal degradation due to wear and tear, leading to inconsistent electrical performance and compromised data integrity.

- Spring-Loaded Pins: These pins can also experience signal degradation, especially if they become dirty or damaged.

- Alignment Issues

- ZIF Connectors: Precise alignment is required during mating, which can be challenging to achieve consistently. Misalignment can lead to poor electrical contact, intermittent connections, and unreliable test outcomes.

- Spring-Loaded Pins: Ensuring proper alignment with spring-loaded pins can be difficult, leading to similar issues with poor contact and unreliable testing.

- Susceptibility to Environmental Factors

- ZIF Connectors: Sensitive to temperature fluctuations, humidity, and dust, which can affect their performance and longevity. In harsh operating conditions, these connectors may degrade more rapidly.

- Spring-Loaded Pins: Environmental factors can also affect these pins, causing them to degrade and require frequent replacements.

- Risk of Device Damage

- ZIF Connectors: The sharp pins of ZIF connectors can damage the delicate pads on the FPC, leading to complications during final assembly.

- Spring-Loaded Pins: Spring-loaded pins can also damage the device under test if not properly aligned or if excessive force is applied.

- Complex Maintenance

- ZIF Connectors: Maintaining and servicing ZIF connectors can be complex and time-consuming, involving intricate procedures for cleaning, inspection, and replacement of components.

- Spring-Loaded Pins: While easier to replace, these pins still require regular maintenance to ensure they remain clean and functional.

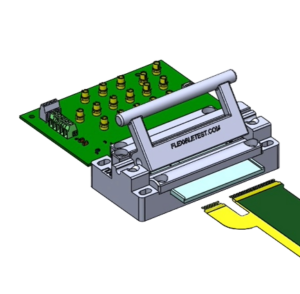

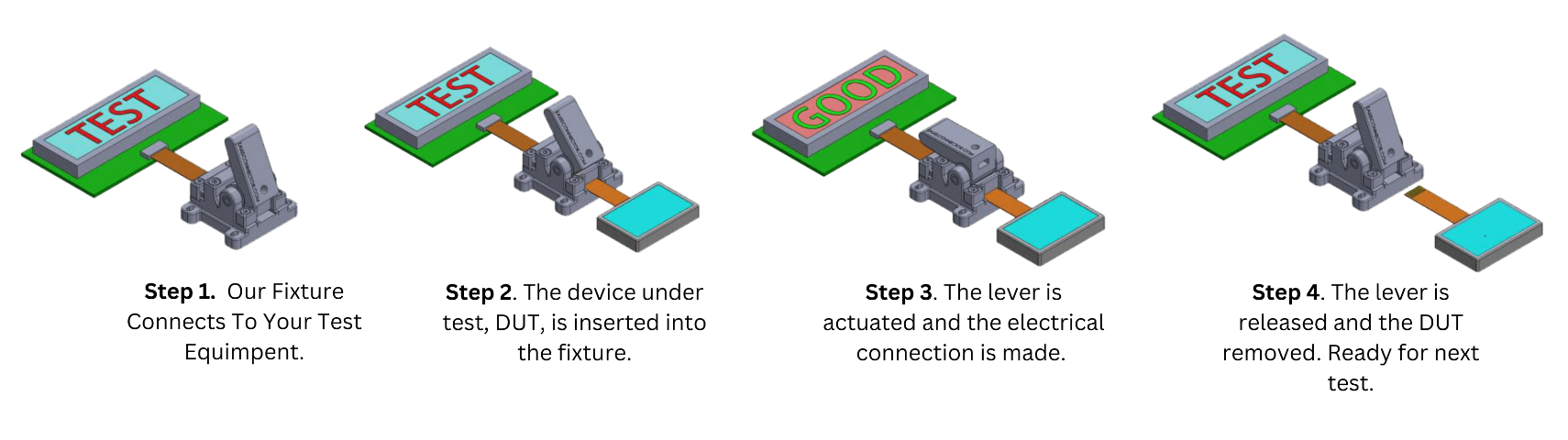

Flexible Test’s Solution

Fortunately, Flexible Test has recognized this need for a dedicated interposer for flat flex cables that addresses all of these issues. A popular fixture is the PCB terminated FFC test fixture, which allows customers to solder their discrete wires directly to the termination PCB. This provides even better signal integrity and allows for a wide variety of applications.

Benefits of Flexible Test Fixtures

- High Cycle Life:

- Designed for repeated use, these fixtures can withstand a high number of mate and de-mate cycles without degrading.

- Superior Signal Integrity:

- The robust design ensures consistent and reliable signal transmission, reducing the risk of data integrity issues.

- Easy Alignment:

- The fixtures are designed for easy and precise alignment, minimizing the risk of misalignment and poor electrical contact.

- Environmental Resilience:

- Resistant to environmental factors, ensuring long-lasting performance even in harsh conditions.

- Device Protection:

- The gentle yet secure connection method prevents damage to the FPC pads, ensuring the integrity of the device under test.

- Simplified Maintenance:

- The fixtures are easy to maintain, reducing downtime and operational costs.

Customers can also use their own custom terminated PCB for the test fixtures, providing flexibility and adaptability to meet specific testing requirements.

By choosing Flexible Test fixtures, manufacturers can overcome the limitations of standard ZIF connectors and pogo pins, ensuring reliable, efficient, and cost-effective testing processes.

Contact us today!