Enhance Your Incoming and Outgoing Inspections with Flexible Test

High-Speed Cable Tester From Flexible Test

From intricate medical devices to cutting-edge consumer electronics, FFCs serve as the lifelines that enable the seamless transmission of signals in compact and complex applications. Whether connecting components in medical probes, powering displays in smartphones, or facilitating communication in automotive control systems, FFCs are the unsung heroes that underpin the functionality of countless electronic devices. In this blog post, we explore how Flexible Test’s FFC Test Fixtures can revolutionize your inspection processes, providing efficiency, precision, and peace of mind.

Understanding the Significance of Incoming and Outgoing Inspections

Before delving into the solution, let’s underscore the importance of incoming and outgoing inspections in the realm of FFC cables. Incoming inspections act as the first line of defense, ensuring that the FFC cables received meet the required specifications. On the other hand, outgoing inspections guarantee that the cables leaving your facility are free from defects, meeting industry standards and customer expectations. Both processes are critical in maintaining product quality, preventing costly issues down the line, and building trust with customers.

Challenges in Traditional Inspection Methods

Traditional methods often come with their own set of challenges, leading to disruptions, increased maintenance costs, and compromised reliability. Two common pain points that manufacturers frequently encounter are failing Zero Insertion Force (ZIF) lock connectors and reliance on pogo pins. Let’s explore these issues and unveil how Flexible Test’s FFC Test Fixtures provide a breakthrough solution.

1. Fragility of ZIF Lock Connectors:

- ZIF lock connectors, while widely used, pose a significant vulnerability in traditional testing setups. Their delicate design makes them prone to frequent failures, especially in high-cycling environments. Each failure translates to downtime as technicians scramble to diagnose and replace the faulty connectors, leading to disruptions in production schedules and increased maintenance costs.

2. Dependence on Pogo Pins:

- Pogo pins have long been a staple in electronics testing, offering a spring-loaded solution for establishing temporary connections. However, their dependence on mechanical contact introduces a host of issues. Over time, pogo pins can wear out, leading to inconsistent connections, false readings, and increased maintenance demands. The need for precise alignment and constant adjustments further adds complexity to the testing process.

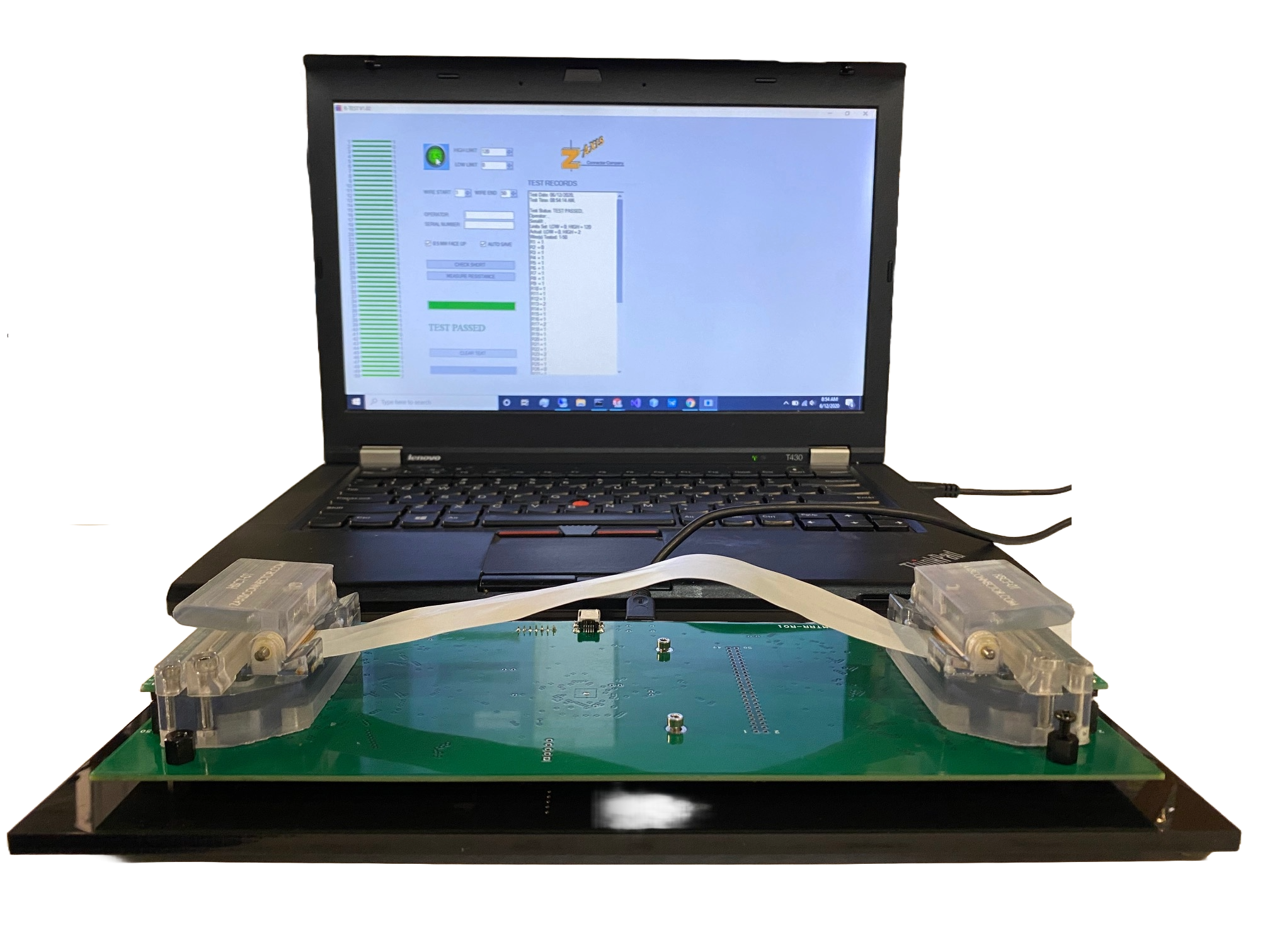

Flexible Test’s Solution: Flexible Test breaks free from the limitations of pogo pins. Our FFC Test Fixtures offer a revolutionary alternative, incorporating an innovative elastomeric connector. This soft yet durable connector ensures a reliable and consistent connection with your Device Under Test (DUT). With an intuitive design that minimizes wear on the DUT, our fixtures provide a seamless testing experience without the headaches associated with pogo pins.

The Flexible Test Advantage: FFC Test Fixtures

Flexible Test’s FFC Test Fixtures are designed with precision and efficiency in mind, addressing the pain points associated with traditional inspection methods. Let’s explore how these fixtures can enhance your incoming and outgoing inspections:

1. Streamlined Setup for Incoming Inspections:

- Flexible Test’s fixtures provide a hassle-free, drop-in solution for incoming inspections. No need for complex configurations or intricate adjustments. Simply integrate the FFC Test Fixture into your setup, and let it do the heavy lifting. The streamlined setup ensures that your incoming inspections are not just thorough but also efficient.

2. Precision in Outgoing Inspections:

- For outgoing inspections, precision is key. Flexible Test’s FFC Test Fixtures facilitate a secure and temporary connection between the FFC cable and the testing equipment. This ensures that every cable leaving your facility has undergone a meticulous inspection, meeting the highest quality standards. The fixtures’ innovative design allows for consistent and reliable connections, guaranteeing the performance of each FFC cable.

3. Comprehensive Testing Capabilities:

- Flexible Test’s FFC Test Fixtures go beyond the basics. They enable comprehensive testing, including checks for continuity, insulation resistance, impedance, and more. The fixtures provide a detailed analysis of the FFC cable’s performance, offering insights that might be missed in traditional visual inspections. This level of thoroughness contributes to the longevity and reliability of the cables in your production.

4. Time and Cost Efficiency:

- Time is money in manufacturing, and Flexible Test understands the value of both. The fixtures are engineered for efficiency, minimizing the time required for inspections without compromising on quality. With reduced testing times, you can enhance your overall production efficiency and meet deadlines with confidence.

5. Expert Support Throughout:

- At Flexible Test, we’re not just providing fixtures; we’re offering a partnership. Our expert support team is ready to assist you at every step. From selecting the right fixture for your needs to providing technical support, we ensure that your inspection processes run seamlessly. Your success is our priority.

Conclusion: Elevate Your Inspection Processes with Flexible Test

In the dynamic landscape of electronics manufacturing, where precision and efficiency are non-negotiable, Flexible Test’s FFC Test Fixtures emerge as a game-changer. By enhancing both incoming and outgoing inspections, these fixtures contribute to the overall quality, reliability, and efficiency of your FFC cables. Say goodbye to the limitations of traditional inspection methods and embrace a new era of testing with Flexible Test.

Are you ready to revolutionize your inspection processes?

Reach out to Flexible Test today and discover how our FFC Test Fixtures can elevate the reliability of your FFC cable connections.