The Distinct Benefits of FFC Test Connectors Versus Traditional Solutions

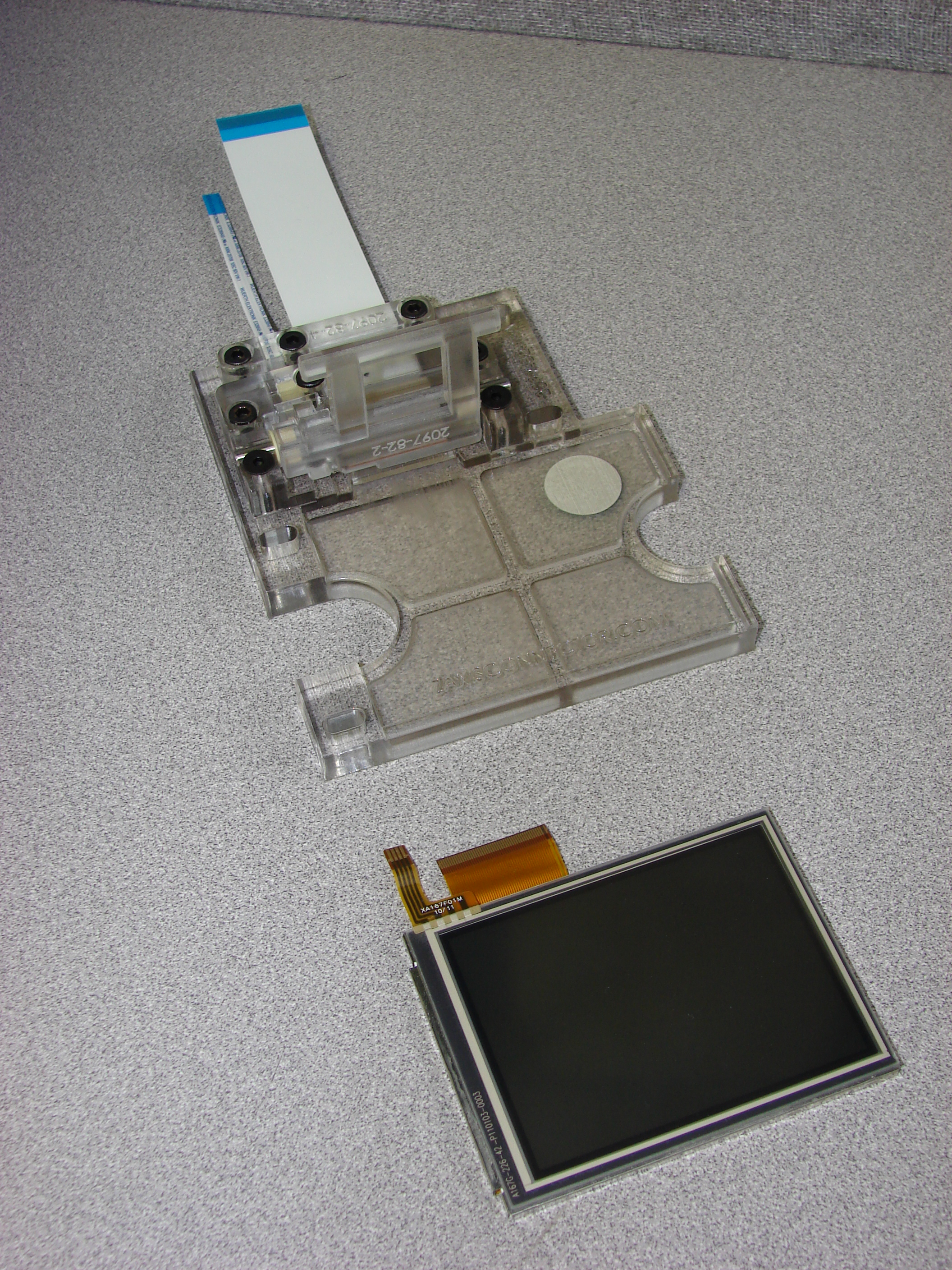

A Flexible Test Fixture interfacing with a TFT Display

In modern electronics, there is one unifying element stands out: the prevalence of highly dense interconnected subsystems. Facilitating these connections are flat flex cables, more commonly known as FFCs. These cables serve as the lifeblood of electronic devices, carrying crucial signal and power traces required by various subsystems.

Among the connectors used for FFCs, the zero-insertion force (ZIF) connector has long been a staple. However, despite its advantages, ZIF connectors are not without their challenges—they are not rated for high mate/demate cycles and are often prone to fragility, particularly in the pins forming the electrical connection with the device under test (DUT).

In this post, we explore how FlexibleTest emerges as a innovative leader in addressing the vulnerabilities of traditional ZIF connectors, offering a solution that enhances durability, reliability, and overall testing efficiency.

The Challenge with Traditional ZIF Connectors

While ZIF connectors have played a crucial role in facilitating the connection between FFCs and subsystems, their limitations have become increasingly apparent. The high-density nature of modern electronics demands connectors that can withstand repeated mate/demate cycles, ensuring longevity and reliability in testing processes. Unfortunately, ZIF connectors fall short in this regard, leading to increased fragility and a susceptibility to failure over time.

The delicate pins used in ZIF connectors, which establish the electrical connection with the DUT, are particularly vulnerable to wear and tear. As these connectors undergo mate/demate cycles, the risk of breakage and failure becomes a significant concern, resulting in downtime, added costs, and disruptions to testing routines.

As valuable as Zero-Insertion Force (ZIF) connectors have been in connecting Flexible Flat Cables (FFCs) to subsystems in modern electronics, they come with their own set of vulnerabilities. The high-density environment they operate in demands a level of resilience that, unfortunately, ZIF connectors often struggle to deliver. Here’s a closer look at some of the common failures associated with traditional ZIF connectors:

- Pin Breakage:

- Delicate pins, the essential components forming the electrical connection with the Device Under Test (DUT), are prone to breakage. The repeated mate/demate cycles that occur during testing contribute to the gradual wear and tear of these pins. Once broken, the connector becomes unreliable, compromising the integrity of the testing process.

- Contact Wear:

- The very nature of ZIF connectors involves physical contact between pins and the corresponding contacts on the DUT. Over time, this constant interaction leads to wear on both the pins and the contacts. As wear progresses, it introduces resistance and can eventually result in an unreliable electrical connection, negatively impacting the accuracy of test results.

- Alignment Issues:

- Precision is key in the world of electronics testing. ZIF connectors, however, are susceptible to alignment issues. Misalignment during the mate/demate process can lead to incomplete connections or, in more severe cases, damage to the pins and contacts. This lack of alignment not only compromises testing accuracy but also poses the risk of damaging the very components they are meant to test.

- Limited Mate/Demate Cycles:

- ZIF connectors are not designed for an indefinite number of mate/demate cycles. Unlike some testing environments that demand high-frequency testing, ZIF connectors have a limited lifespan in terms of the cycles they can endure. Once this limit is reached, the connector becomes prone to failure, necessitating replacements and causing downtime in testing procedures.

- Environmental Sensitivity:

- ZIF connectors can be sensitive to environmental factors such as temperature, humidity, and dust. Extreme conditions can exacerbate their vulnerabilities, leading to a higher likelihood of failure. In industries where testing environments may not be easily controlled, the susceptibility of ZIF connectors to environmental factors becomes a considerable concern.

- Cumulative Damage:

- With each mate/demate cycle, ZIF connectors accumulate a degree of damage. Over time, this cumulative effect can compromise the structural integrity of the connector. Even if individual pins do not break, the overall wear and tear can lead to a decline in performance and reliability, making routine replacements necessary.

Understanding these common failures sheds light on the challenges associated with traditional ZIF connectors. As electronic devices continue to advance in complexity and density, addressing these vulnerabilities becomes paramount. It is in overcoming these challenges that the innovation and resilience of FlexibleTest’s fixtures truly shine.

FlexibleTest: The Solution to Fragile ZIF Connectors

FlexibleTest develops cutting-edge solutions designed to improve FFC device testing workflows. FlexibleTest has identified the challenges posed by traditional ZIF connectors and has crafted fixtures that not only overcome these issues but also elevate the testing experience to new heights.

- Durability Beyond Limits:

- FlexibleTest’s fixtures are engineered with durability as a top priority. With an impressive rating of 20,000 cycles, these fixtures are built to endure the demands of high mate/demate cycles without compromising on performance. Say goodbye to the fragility associated with traditional ZIF connectors, as FlexibleTest’s fixtures redefine what it means to be robust and long-lasting.

- At the core of FlexibleTest’s fixtures is a commitment to quality materials. Constructed from high-quality substances such as aluminum or veroclear, these fixtures are engineered to endure the most challenging testing environments. The choice of materials not only enhances durability but also contributes to the overall reliability of the fixtures, making them a trustworthy asset in diverse testing scenarios.

- Field-Replaceable Components:

- Recognizing that wear and tear are inevitable, FlexibleTest takes it a step further by offering field-replaceable components. When a connector needs replacement, there’s no need for extensive downtime or intricate procedures. FlexibleTest’s fixtures are designed for easy field replacement, minimizing disruptions and ensuring that your testing process remains efficient and uninterrupted.

- The majority of standard FFC connectors lack the field-replaceable feature, leading to significant challenges when maintenance is required. In contrast, FlexibleTest’s fixtures break away from these limitations, providing a revolutionary solution to the common issues associated with connector replacements. The absence of this feature in traditional methods often translates to increased time and costs associated with repairs—a burden that FlexibleTest effectively alleviates

- Reliability Unmatched:

- In the world of device testing, reliability is paramount. FlexibleTest understands this critical requirement and has meticulously crafted fixtures that consistently deliver reliable results, test after test. Eliminate the uncertainty associated with fragile ZIF connectors, and embrace a testing process that you can trust for accurate and dependable outcomes.

- Adapting to Testing Environments

- Versatility is a key attribute of FlexibleTest’s fixtures. Designed to withstand a variety of testing environments, these fixtures exhibit resilience in the face of factors such as temperature variations, humidity, and other challenging conditions. Whether your testing environment is meticulously controlled or subject to fluctuations, FlexibleTest’s fixtures prove to be a steadfast companion, consistently delivering optimal performance.

- Customization Tailored to You:

- Recognizing that not all testing requirements are the same, FlexibleTest offers customization options. Tailor the fixtures to meet your unique needs, ensuring that you have the right tool for the job. This level of customization is particularly valuable in industries where standardization may not align with specific testing demands.

- The value of customization is particularly pronounced in industries where standardization falls short of meeting specific testing demands. Whether you operate in aerospace, automotive, healthcare, or any other sector, each industry has its own set of unique requirements. FlexibleTest recognizes this diversity and provides a platform where your testing fixtures can be customized to align seamlessly with your industry’s distinct needs.

- Expert Support Every Step of the Way:

- Transitioning to a new testing solution can be daunting, but with FlexibleTest, you’re not alone. Their team of experts is ready to assist you at every step, from selecting the right fixture to providing ongoing technical support. Benefit from a partnership that goes beyond the product, ensuring that you are fully supported in optimizing your testing processes.

Conclusion

As the demand for robust and reliable testing solutions continues to rise, FlexibleTest emerges as a beacon of innovation in the field of FFC device testing. By addressing the fragility and limitations of traditional ZIF connectors, FlexibleTest’s fixtures redefine industry standards, offering durability, reliability, field-replaceable components, customization options, and expert support.

Don’t let fragile ZIF connectors hinder your testing efficiency any longer. Choose FlexibleTest for a transformative solution that enhances the durability and reliability of your testing processes. Contact FlexibleTest today and experience firsthand how their cutting-edge fixtures can elevate your electronics testing to new heights. With FlexibleTest, say goodbye to fragility and welcome a new era of robust, efficient, and cost-effective FFC device testing.