Update Your Electronics Testing with Flexible Test

In the ever-evolving landscape of electronics, precision and reliability are paramount. Ensuring the quality and functionality of electronic devices, from the smallest components to complex systems, demands rigorous testing processes. Enter the unsung hero of electronics testing – the electronics test fixture. In this comprehensive guide, we explore the world of electronics test fixtures and unveil how Flexible Test, with over 25 years of experience, is revolutionizing the industry with fixtures that are both drop-in ready and fully customizable.

Understanding the Significance of Electronics Test Fixtures

Picture this: a state-of-the-art electronic device that’s been meticulously designed, a culmination of time, effort, and innovation. It’s ready to hit the market, but before it can take its place in the hands of consumers, it must undergo extensive testing.

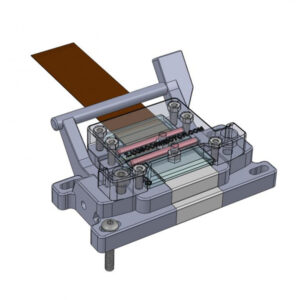

That’s where the electronics test fixture comes into play. This unassuming piece of equipment is an essential part of the quality assurance process. Electronics test fixtures are specialized devices designed to establish an electrical connection between a device under test (DUT) and testing or inspection systems. They play a pivotal role in validating the functionality and reliability of electronic components, ensuring that every device meets the rigorous standards expected in the modern electronics industry.

The Flexible Test Difference: Over 25 Years of Expertise

For over a quarter of a century, Flexible Test has been at the forefront of designing and providing products for electronics test fixtures. With this wealth of experience, we understand the intricate needs of the industry and have continuously evolved to meet and exceed those demands.

Our extensive experience means that we have witnessed the rapid transformation of the electronics landscape. From the advent of cutting-edge devices to the development of complex systems, we’ve been there every step of the way. We’ve seen how the industry’s requirements have grown, demanding more precision, adaptability, and efficiency in electronics testing. Flexible Test has adapted and innovated over the years to stay ahead of these challenges, making us a trusted partner for all your testing needs.

Customization: Tailoring Fixtures to Your Needs

One of the key strengths of Flexible Test is our commitment to customization. We understand that no two testing requirements are the same. Whether you need a fixture that seamlessly integrates into your existing setup or one that’s built from the ground up to meet specific and unique requirements, we have you covered.

Our fixtures can be dropped into an existing test setup, streamlining your testing process without the need for complex configurations or adjustments. This adaptability is a testament to our commitment to enhancing your workflow and saving you both time and cost. But our flexibility doesn’t stop there.

Revolutionary Connectors: Field-Replaceable and Highly Customizable

Inside every Flexible Test fixture lies a critical component – our unique connectors that form the electrical bridge between your DUT and testing equipment. These connectors are not just any run-of-the-mill connectors; they are engineered to be both field-replaceable and highly customizable.

Imagine the scenario: you’re in the midst of a critical testing phase, and one of the connectors experiences an issue. In a traditional setup, this could spell a significant interruption as you troubleshoot and replace the connector. But with Flexible Test, our connectors can be field-replaced in a matter of minutes. It’s a game-changing feature that minimizes downtime and ensures your testing process remains efficient and uninterrupted.

Customization is another hallmark of our connectors. We understand that the specific requirements of your testing processes can vary widely. With our connectors, you have the flexibility to tailor them to your unique needs. Whether it’s a specialized configuration, material choice, or specific pin layout, we can work with you to create connectors that align perfectly with your testing goals.

The Benefits of Flexible Test Fixtures

- Efficiency:

- Streamlined Testing Processes

- In the fast-paced world of electronics testing, efficiency is key. Flexible Test Fixtures are designed to streamline your testing processes, reducing the need for complex configurations and adjustments. Our fixtures can be seamlessly integrated into your existing setup, saving you valuable time and effort. This means that your testing operations can run smoothly without the hiccups caused by complicated installations and setups. By minimizing the time spent on setup, you can focus on what really matters – accurate and reliable testing.

- Streamlined Testing Processes

- Downtime Reduction:

- Uninterrupted Testing

- Downtime is the enemy of productivity, especially in the world of electronics testing. When a component fails, or a connector breaks, it often results in significant downtime as technicians work to diagnose and replace the faulty part. Flexible Test Fixtures combat this issue by offering field-replaceable connectors. These connectors can be swapped out in a matter of minutes, ensuring that your testing process can continue without long interruptions. By reducing downtime, you can maintain the efficiency of your testing operations, ultimately saving both time and resources.

- Uninterrupted Testing

- Cost Savings:

- Minimizing Disruptions

- Frequent disruptions and the need for constant replacements can lead to soaring maintenance costs. Traditional fixtures often require replacements and repairs, which can strain your budget. With Flexible Test Fixtures, you can significantly reduce these disruptions and the associated costs. Our field-replaceable connectors and durable engineering ensure that you won’t be constantly replacing components. This cost-saving feature not only keeps your budget in check but also enhances the long-term cost-effectiveness of your testing processes.

- Minimizing Disruptions

- Reliability:

- Consistent and Dependable Results

- In the world of electronics testing, consistency and reliability are non-negotiable. With over two decades of experience in the industry, Flexible Test has honed the art of engineering fixtures that consistently deliver dependable results, test after test. Our fixtures are built to endure thousands of cycles, ensuring long-lasting reliability and eliminating broken latches for good. When you choose Flexible Test, you’re choosing reliability, reducing the risk of errors and ensuring that every test yields the expected results.

- Consistent and Dependable Results

- Customization:

- Tailoring to Unique Requirements

- We understand that not all testing requirements are the same. Your specific testing needs may vary, and that’s where our highly customizable connectors and fixtures shine. Whether you require a specialized configuration, material choice, or a unique pin layout, we can work closely with you to tailor our products to meet your exact requirements. This level of customization ensures that our fixtures align perfectly with your testing goals, making it a perfect fit for your specific testing processes. With Flexible Test, it’s not one-size-fits-all; it’s one-size-fits-your-needs.

- Tailoring to Unique Requirements

Conclusion: The Future of Electronics Testing with Flexible Test

As electronics continue to evolve, the demands on testing processes are growing. Precision, reliability, and adaptability are no longer just desirable but imperative. Flexible Test, with over 25 years of experience, stands as a beacon of innovation in the world of electronics test fixtures.

Our fixtures are not just equipment; they’re solutions tailored to meet your unique needs. Whether you require a drop-in fixture that streamlines your testing process or a fully customized solution, we have the expertise and flexibility to make it happen.

Join us in embracing the future of electronics testing. Let’s make your testing processes efficient, cost-effective, and reliable, one fixture at a time. Connect with Flexible Test and experience the next generation of electronics test fixtures, revolutionizing the way you ensure quality in your electronic devices.